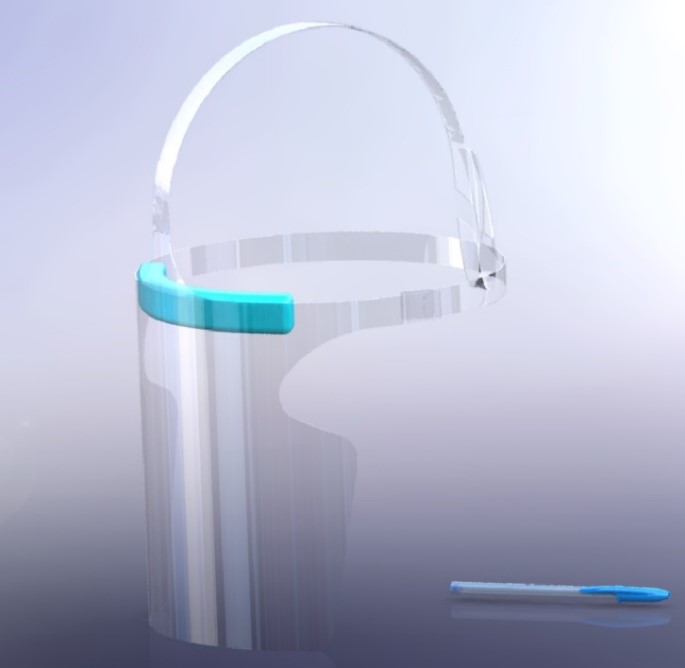

Strataglass Face Shield: A Simple, Three-Component DIY Design

Strataglass and Herculite are pleased to offer our customers a simple and effective Face Shield design and pattern that can be quickly assembled with just three (3) components; Strataglass clear vinyl, adhesive backed foam and adhesive backed hook and loop Velcro.

WE ARE PROVIDING THIS AS A DESIGN GUIDE FOR YOUR OPTIONAL USE.

- Easy to manufacture and assemble

- No sewing required

- Flexible for comfort

- Multi-Use

- Can be easily cleaned with alcohol

- No sharp edges

- Ultra-clear, distortion free

- Easily deployed and shipped

- Light weight

- Strataglass is engineered to be scratch resistant

- Follow CDC guidelines and wash hands before manufacturing

- NOT AN FDA REGISTERED DEVICE

- NOTE: Strataglass makes NO CLAIM that these face shields will protect you from contracting any virus or disease. Use at your own risk. These face shields are meant to be used in conjunction with CDC approved masks and eyewear.

Manufacturing and Assembly Instructions

- Purchase Strataglass products from an Authorized Distributor

- Download the pattern CAD file here:

- CAD is converted to CAM in G-Code for a plotter.

- The dimensions could also be programmed manually

from the attached if necessary by someone who knows how to write G-Code.

from the attached if necessary by someone who knows how to write G-Code. - Cut the shields out of the clear vinyl sheet preferably using a Cutter Plotter. One clear vinyl sheet will yield 14 Face Shields.

- Attach an 8” Long X 1.5” Wide x 1” Thick adhesive backed foam to the shield in the forehead area. ¼” – ½” from top edge.

- Attach 3” pieces of adhesive backed hook and loop tape to the ends of the straps.

- To deploy, place shield over face and secure in place by connecting the straps with the Velcro.

0 Comments